All about Caster Manufacturer

Wiki Article

9 Simple Techniques For Caster Manufacturer

Table of ContentsCaster Manufacturer for DummiesCaster Manufacturer Fundamentals ExplainedExamine This Report on Caster ManufacturerRumored Buzz on Caster ManufacturerCaster Manufacturer - The Facts

Undriven wheel that is designed to be connected to all-time low of a bigger object A caster (or castor) is an undriven wheel that is created to be affixed to the bottom of a bigger object (the "automobile") to enable that things to be relocated. Wheels are utilized in countless applications, consisting of purchasing carts, workplace chairs, plaything wagons, hospital beds, as well as material handling devices. Dawing of a swievelling wheel from Codex Lffelholz, Nuremberg 1505 Casters might be taken care of to roll along a straight line path, or placed on a pivot or pintle such that the wheel will immediately align itself to the instructions of traveling. A standard, stiff caster consists of a wheel installed to a stationary fork.

An example of this is the wheels located at the back of a purchasing cart in North America. Rigid casters often tend to restrict automobile motion so that the car takes a trip along a straight line.

When the wheel is moved and also the wheel is not dealing with the right direction, the offset will certainly create the wheel setting up to turn around the axis of the vertical shaft to follow behind the direction of movement. If there is no balanced out, the wheel will certainly not turn otherwise facing the right direction, either preventing activity or dragging across the ground.

This can be seen on a buying cart when the front wheels straighten alongside the rear wheels when traveling down an aisle. A consequence of this is that the car normally often tends to travel in a straight instructions. Accurate guiding is not needed because the wheels often tend to maintain straight movement.

Caster Manufacturer Fundamentals Explained

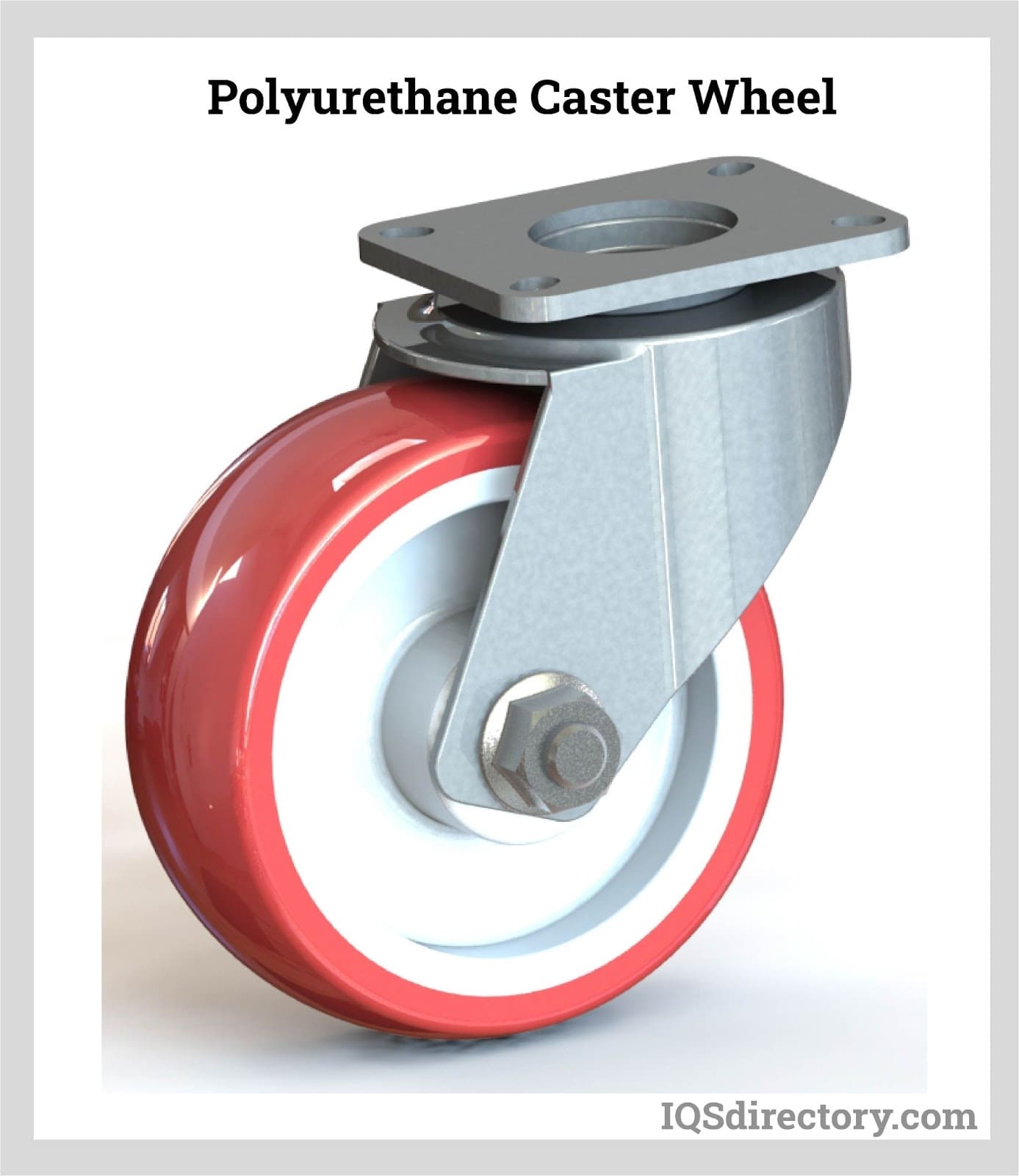

The caster turns perpendicular to the turning distance and also offers a smooth turn. This can be seen on a purchasing cart as the front wheels rotate at different velocities, with different turning radius depending upon exactly how tight a turn is made. The angle of, and range in between the wheel axles and also swivel joint can be changed for various kinds of caster performance.Industrial casters are heavy duty casters that are designed to bring heavy loads, in some instances up to thirty thousand extra pounds. An Industrial wheel might have either a swivel or rigid caster design. Industrial wheels normally have a flat top plate that has four bolt openings to make sure a strong link in between the top plate and the load.

A more complicated kind of swivel wheel, occasionally called a complete lock caster, has an additional rotational lock on the upright shaft so that neither shaft swiveling nor wheel rotation can take place, therefore providing very rigid support. It is feasible to utilize these two locks with each other or independently. If the vertical shaft is secured however the wheel can still transform, the caster comes to be a directional wheel, but one which might be locked to roll in one direction along any straight axis.

This system has no kingpin, hence the name kingpinless. The lack of an authority eliminates most reasons for swivel caster failure [] and minimizes internet or removes shimmy after use [] They use capacity as well as toughness comparable to units having actually sealed accuracy round or tapered bearings [], as well as are an useful option to standard swivel casters in high-impact situations []

How Caster Manufacturer can Save You Time, Stress, and Money.

A common basics example of wheel flutter is on a supermarket buying cart, when one caster quickly swings side-to-side. The speed at which caster flutter happens is based on the weight birthed by the wheel and the range between the wheel axle and guiding axis.Flutter takes place when the caster is not in full call with the ground and therefore its alignment is irrepressible. As the caster gains back full call with the ground, it can be in any kind of orientation.

At slower rates, the wheel's capacity to swivel can fix the instructions as well as can proceed travel in the wanted direction. At high rates this can be harmful as the wheel may not be able to rotate rapidly sufficient as well as the lorry may stumble in any type of instructions. Electric and also racing wheelchair developers are extremely worried about flutter because the chair should be secure for cyclists.

The rubbing enhances as the weight on the front of the chair boosts. Anytime the wheel starts to tremble, it reduces the chair as well as changes weight to the front wheels. There are several online anti-flutter kits for retrofitting mobility device casters in this way. Other methods of lowering caster flutter include enhancing swivel lead, utilizing much heavier grease, minimizing the mass of the wheel, or raising friction with the ground by transforming materials.

Our Caster Manufacturer Diaries

visit our website Ergonomic wheels are created with factor to consider for the operating setting and also the task to be done so that any kind of injurious impacts on the operator are lessened. Lasting repeated actions entailing resisting casters can add to strain injuries.Big diameter wheel wheels are able to link voids like that between the flooring and also a lift automobile. However, the larger the size of a caster wheel, the greater the wheel assistance arm need to be. Either the base of a low-hanging object should be raised greater over the wheels, or the wheels should socialize to the sides straddling the low-hanging supported things.

Bigger wheels need more of this space. Lots ability may be boosted by utilizing broader wheels with more ground contact location. When revolving a wide swivel caster in-place, the facility part of the wheel-to-ground get in touch with patch revolves slower than the areas additionally out to the sides. This difference in rotation rate throughout the base of the wheel contact spot causes wide wheels to withstand rotation around the swivel, as well as this resistance enhances as weight packing increases.

Each wheel has a comparatively narrower ground call spot than a solitary large wheel, so there is less resistance to turning in position on the swivel. There are 4 major classifications of wheels: A common wheel has a center revolving hub (or bearing) and a certified product on its external side.

Getting My Caster Manufacturer To Work

, or Swedish wheel) is made of a huge central center with lots of extra smaller wheels mounted along the border such that their axes are vertical to the main wheel. The central wheel can rotate around its axis like typical wheels, but the smaller sized wheels can also make it possible for activity vertical to the central axis.

An example is a round transfer unit (Caster Manufacturer).

Report this wiki page